High Barrier Packaging Films Market Size to Worth USD 28.38 Billion by 2034 | CAGR of 6.27% during 2026-2034

Global high barrier packaging market poised to grow from USD 16.53 billion in 2025 to USD 28.38 billion by 2034 at a CAGR of 6.27%

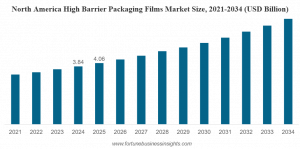

NEW YORK, NY, UNITED STATES, February 4, 2026 /EINPresswire.com/ -- Global Market OverviewThe global high barrier packaging films market size was valued at USD 16.53 billion in 2025. The market is projected to grow from USD 17.45 billion in 2026 to USD 28.38 billion by 2034, exhibiting a CAGR of 6.27% during the forecast period.

The high barrier packaging films market is witnessing steady growth, driven by increasing demand for extended shelf life, product protection, and convenience packaging across food, pharmaceutical, and personal care industries. These films offer strong resistance against moisture, oxygen, light, and contaminants, making them essential for preserving product quality and freshness. Rising consumption of packaged and processed foods, along with growth in e-commerce and pharmaceutical packaging, is supporting global market expansion.

Get a Free Sample of this Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/high-barrier-packaging-films-market-111149

Key Market Insights

High barrier packaging films are experiencing increasing adoption across food, pharmaceutical, and industrial packaging applications due to their superior protection capabilities compared to conventional packaging materials. These films provide excellent resistance to moisture, oxygen, light, and contaminants, thereby extending product shelf life and preserving quality. The integration of multilayer structures, combining materials such as polyethylene, polypropylene, EVOH, and polyamide, allows manufacturers to optimize barrier performance while minimizing overall material consumption. In parallel, advanced coating technologies, including aluminum oxide and silicon oxide coatings, are enabling thinner films with enhanced functional properties and improved process efficiency. Growing sustainability concerns are significantly shaping product development strategies, as brand owners and regulators emphasize reduced environmental impact. As a result, manufacturers are increasingly investing in recyclable mono-material structures and bio-based high barrier films that support circular economy goals. These innovations are not only addressing regulatory and consumer sustainability expectations but also helping companies achieve cost efficiency and improved packaging performance.

Market Trends

The market is witnessing a strong transition toward lightweight and sustainable packaging solutions as manufacturers and brand owners aim to reduce material usage and environmental impact. Recyclable mono-material high barrier films are gaining significant traction, especially in food and beverage applications, where maintaining freshness and extending shelf life are critical. Continuous technological advancements, including vacuum deposition techniques, aluminum oxide and silicon oxide coatings, and advanced nanocoatings, are enhancing barrier efficiency without compromising flexibility or recyclability. Additionally, growing demand for product differentiation is driving customization in packaging designs. Smart packaging features, such as QR codes, freshness indicators, and traceability solutions, are also emerging as key trends, supporting improved consumer engagement, supply chain transparency, and brand value.

Market Growth Factors

Market growth is primarily driven by the rising consumption of packaged foods, ready-to-eat meals, and convenience products, fueled by busy lifestyles and increasing preference for on-the-go consumption. The expanding pharmaceutical and medical packaging sectors are further boosting demand, as high barrier packaging is essential to prevent contamination, ensure product integrity, and maintain efficacy. Rapid urbanization, evolving consumer habits, and growing penetration of organized retail in emerging economies are accelerating the adoption of advanced packaging solutions. Additionally, the growth of e-commerce and cold-chain logistics is increasing the need for durable, high-performance packaging. Strict regulatory emphasis on food safety, hygiene standards, and product traceability is also compelling manufacturers to adopt high barrier films, reinforcing long-term market expansion.

Segmentation Analysis

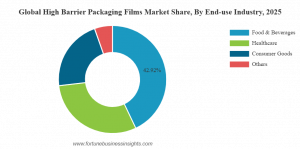

The market is segmented by material type, including polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), polyamide (PA), and others. By product type, it includes metallized films, coated films, and multilayer films. Based on end-use, the market serves food and beverage, pharmaceuticals, personal care, industrial, and others, with food packaging accounting for the largest share.

Speak to Analyst: https://www.fortunebusinessinsights.com/enquiry/speak-to-analyst/high-barrier-packaging-films-market-111149?utm_medium=pie

Regional Analysis

North America and Europe represent mature markets due to strong demand for packaged food and stringent packaging standards. Asia Pacific dominates growth prospects, supported by rapid urbanization, expanding food processing industries, and rising disposable incomes in countries such as China and India. Latin America and the Middle East & Africa are witnessing gradual growth driven by improving retail infrastructure and increasing adoption of modern packaging solutions.

Key Industry Players

• Amcor Plc (Switzerland)

• Sealed Air (U.S.)

• Constantia Flexibles (Austria)

• Glenroy, Inc. (U.S.)

• Winpak Ltd. (Canada)

• Mondi (U.K.)

• Toray Plastics, Inc. (U.S.)

• Schur Flexibles GmbH (Austria)

• Huhtamaki Oyj (Finland)

• ProAmpac (U.S.)

• Flair Flexible Packaging Corporation (Canada)

• Oliver Healthcare Packaging (U.S.)

• C-P Flexible Packaging (U.S.)

• Cosmo Films (India)

• Bagla Group (India)

Key Industry Developments

• December 2025: Cosmo Films broadened its flexible packaging offerings with a new selection of films based on BOPP, CPP, and BOPET, specifically designed for pet food packaging. This launch features a new TR-BOPP film that is highly resistant to heat, as well as enhanced barrier and lidding films, reinforcing the company’s dedication to providing next-generation, food-safe packaging.

• November 2025: TOPPAN Inc., along with its subsidiary based in India, TOPPAN Speciality Films Private Limited (TSF), installed a hybrid manufacturing line that is capable of producing both biaxially-oriented polypropylene (BOPP) film and biaxially-oriented polyethylene (BOPE) on a single machine. With a robust history in the production of BOPP films, TSF is now initiating the film production of BOPE on this new line to meet the growing and diversifying demand.

Future Outlook

The high barrier packaging films market is expected to grow steadily, supported by rising demand for safe, durable, and sustainable packaging. Advancements in material science and recycling technologies will shape future product development. Emerging markets are expected to provide significant growth opportunities as packaged food consumption and pharmaceutical production continue to expand.

Read Related Insights:

Packaging Automation Market

Packaging Coatings Market

Ashwin Arora

Fortune Business Insights™ Pvt. Ltd.

+1 833-909-2966

sales@fortunebusinessinsights.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.